Description

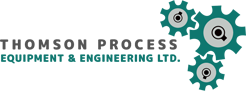

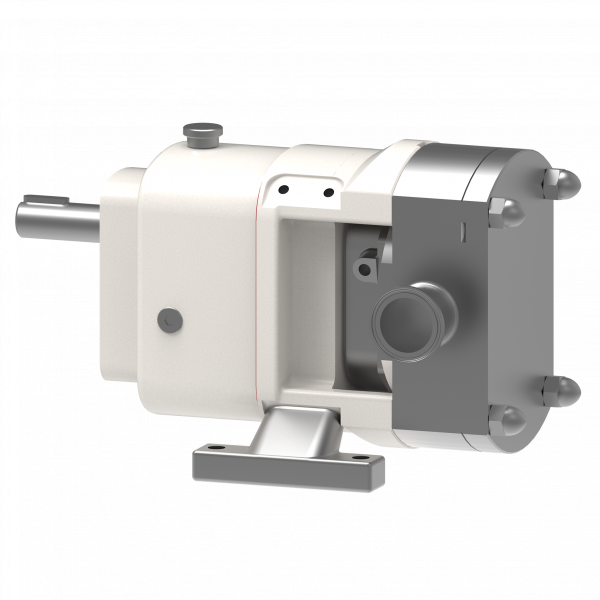

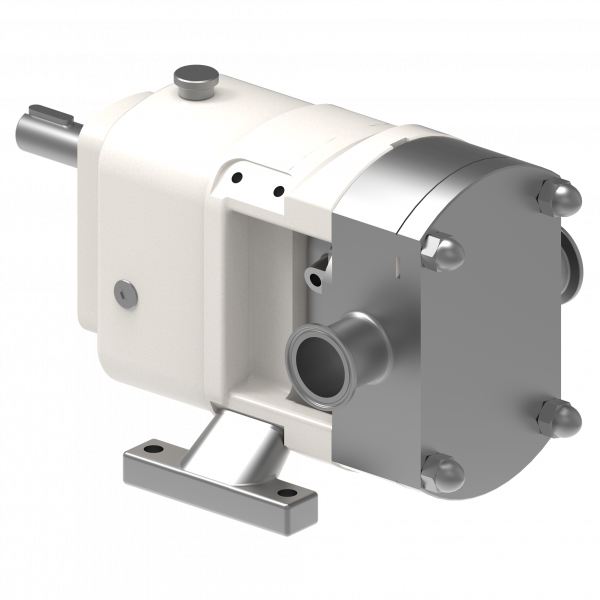

Viking Pump Hygienic Classic+ Multipump, Hygienic Rotary Lobe Pumps for food and pharma applications.

Classic+ (Multipump) is a reliable, proven classic. The Rotary Lobe PD Pump Design has endured the test of time, you will find these traditional rotary lobe pumps working reliably around the globe.

Viking Hygienic Pump Classic + and Multipump is the hygienic pump of choice for many of Ireland’s leading pharmaceutical companies.

An excellent hygienic pump from Wright Flow Technologies the Rotary Lobe Pump manufacturers is the Classic + Multipump – a reliable, proven classic, this pump design has endured the test of time. You will find these traditional rotary lobe pumps working reliably around the globe. A simple & economical solution for hygienic processing needs.

This pump can be used in a variety of applications including pharmaceuticals, personal care products, dairy, chemicals,s and food, and beverages.

Applications of the Viking Pump Hygienic Pump Classic + and Multipump

The Viking Pump Hygienic Pump Rotary Lobe Classic + and Multipump can pump Chemical Products including Raw Ingredients, Chemical Transfer, and Solvent Recovery.

Can pump the following:

- Raw Ingredients

- Chemical Transfer

- Solvent Recovery

Viking Pump Rotary Lobe Pumps for Pumping Personal Care Products, Pumping Cosmetics, Skincare Products Pump, Toothpaste Pump, Shower and Shaving Products Pump and Hair Care Products Pump.

The Classic + Multipump hygienically personal care products/ toiletries and beauty products with ease. The following items work well with this pump:

- Skincare Products

- Toothpaste

- Cosmetics

- Shower & Shaving Products and Liquids

- Hair Care Products

Viking Pump Hygienic Rotary Lobe Pump for Pumping Food & Beverages – especially for brewers pumping beer, distillers pumping botanicals, and vintners pumping a variety of pulp liquids and purees.

Great pump for distillers, brewers, and vintners. An excellent pump for micro-breweries of craft beers, wines, and spirits. It is also very efficient at pumping pulp liquids and purees.

With the Viking Classic+ Rotary Lobe Pump, the following processes and liquids work well:

- Distillers and Vinters

- Fruit and Vegetable Purees

- Carbonated Drinks and Juices

Foods that are easily pumped by the Classic+ & Multipump:

- Baby Food

- Edible Oils

- Soft Fruits and Veg

- Soups and Sauces

- Eggs

- Fish

- Meat

- Poultry

- Whey Proteins

- Confectionary

Dairy products are also compatible with this Rotary Lobe pump:

- Butter

- Cheese

- Cream

- Milk

- Yogurt

- Yogurt Fruits

Viking Pump Hygienic Classic+ and Multipump for Pumping Pharmaceuticals and Biopharma products.

- Medicinal Chemicals

- Creams and Ointments

- Syrups

- Injectibles

- Ultra Filtration

- Blood and Plasma Processing